Research

Research

4 Research Areas

The mission of CAMAL is to be a pioneer in the areas of research and development of rapid prototyping and advanced manufacturing. CAMAL focuses on a wide range of areas:

The results of our research in the areas of rapid prototyping and additive manufacturing have led to many real world successes, including the development and/or testing of:

- Critical EBM parameters that allow the fabrication of titanium allow Ti6AI4V for aerospace components with properties that approach that of forged components

- Near net shape components made in small lot sizes, faster and cheaper than forged components

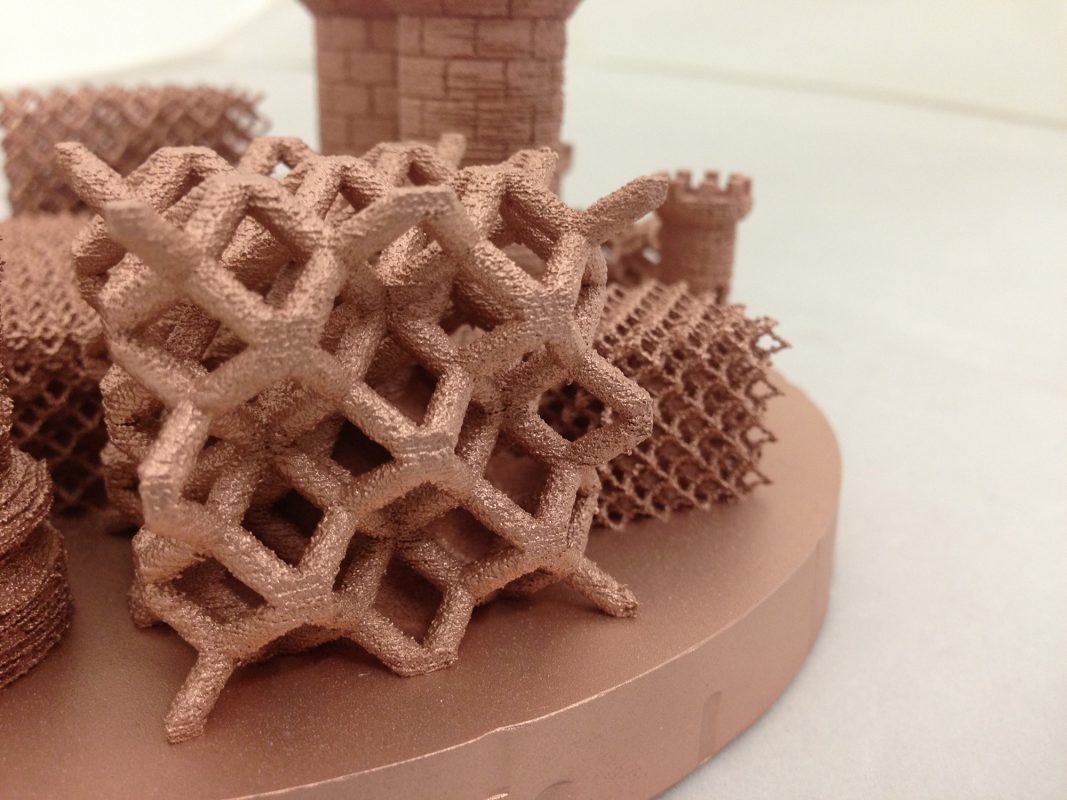

- Energy absorbing and dissipating structures

- Aerospace components with integral conformal cooling channels and optimized heat exchangers

- Custom copper anodes for high energy particle accelerators

- Geometric lattice structures which allow precise control of structural properties while reducing weight

- Conformal cooling channels into part geometries that permit efficient heat transfer where needed Current research includes finding optimal ways to move from near net shape to net shape in parts made with additive metal processes. The recent additions of high precision metal machining technologies from Mazak, haas, and Citizen have greatly enhanced our capabilities in this area. We are, indeed, thinking and doing at CAMAL.

Biomedical

Since our beginning, we have worked with biomedical engineering and veterinary science researchers. This collaboration has been important to our success and growth. ISE researchers have worked with a wide range of medical and veterinary research leaders to:

- Use EBM technology to create customized lattice structures in implants. These optimized frameworks meet specific needs such as bone in growth, strength, thermal conductivity and fluid transfer

- Create customized hip stems and knee implants using DLMS and EBM processes

- Develop customized bone plates to improve the surgical and healing time of fractures

- Create the first ever custom transcutaneous osseointegrated implants for the direct skeletal attachment of a load bearing prosthetic. Dr. Denis Marcellin-Little from the College of Veterinary Medicine at UC Davis has been a vital part of this research.

Are you interested in CAMAL’s Biomedical research? Contact us | camalinforequests@ncsu.edu

Do you want to get involved in our research? Questions on how to partner with CAMAL? Contact us | camalinforequests@ncsu.edu

Hybrid Manufacturing

CAMAL has been active in finding ways to incorporate automation into the challenge of going from the near net-shaped parts produced in various additive metals manufacturing processes to the required net-shaped parts with critical, tight tolerances needed in many industries. This combination of additive manufacturing processes and traditional subtractive manufacturing techniques is referred to as “Hybrid Manufacturing”.

Are you interested in CAMAL’s Hybrid Manufacturing research? Contact us | camalinforequests@ncsu.edu

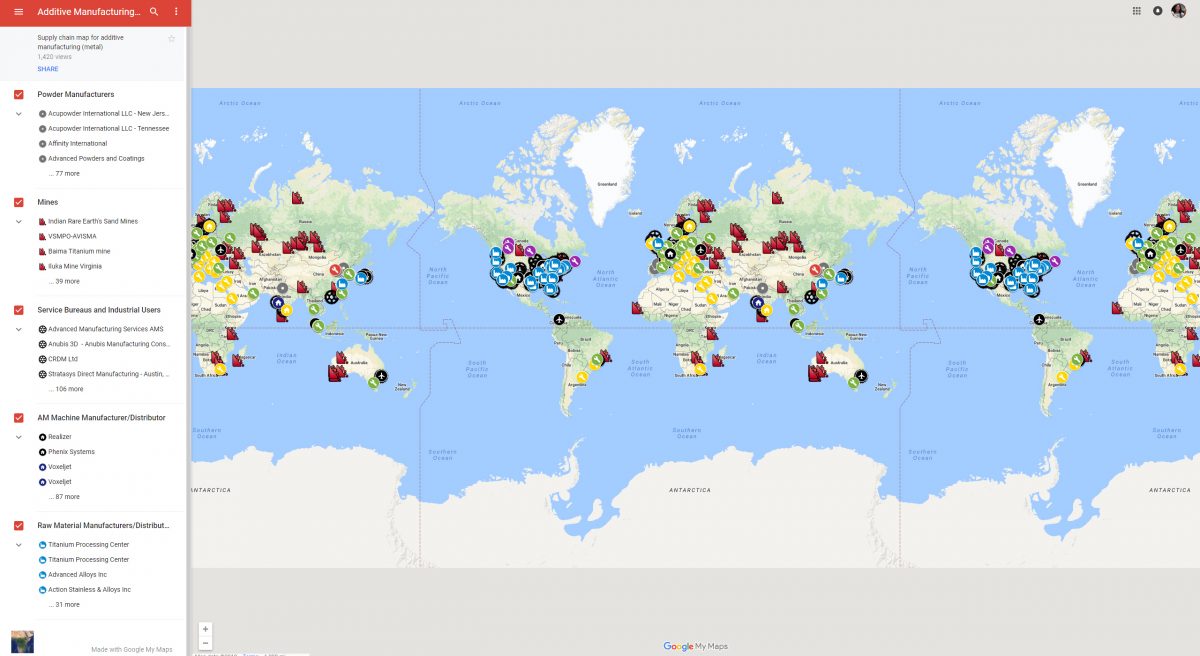

Logistics and Supply Chain

Meeting the ever increasing demand for 3D printed products will be as challenging as developing new additive technologies. NC State ISE, the Poole College of Management and the Institute for Defense and Business are working together to further additive logistics research, education and training. This collaboration enables us to recruit the best talent to optimize the additive supply chain.

Are you interested in CAMAL’s Logistics and Supply Chain research? Contact us | camalinforequests@ncsu.edu

Material Development

Since 2003, CAMAL has been active in the development of EBM process parameters for a variety of alloy systems. The lab has direct metal laser sintering capability with an EOS Model INT 280. We also have an ExOne X1 in our Lab. This gives us a new technology we can use to experiment with ceramic/metal combinations. These technologies combined with our ITAR compliant lab facilities will allow us to remain a world class leader in additive material development. With the ability to fabricate fully dense, near-net shape, metal components with technologies like Electron Beam Melting and Laser Melting, there is an increased interest in developing process parameters for new materials. This includes existing metals and alloys as well as new exotic alloys that may be difficult to process using traditional methods. Our lab has been developing process parameters for the Arcam since 2003 when we purchased the very first commercially available Arcam system. Many types of metal powder can be melted using the Arcam system. A feasibility study can usually be completed with a small amount of material. Below is a brief description of such materials.

Are you interested in CAMAL’s Material Development research? Contact us | camalinforequests@ncsu.edu

Core research programs are supported by funds from the State of North Carolina and our partner companies. The results of the research are proprietary to the College and all partner companies that support the research. After the approval of our Industrial Advisory Board (IAB), this information is placed in the public domain, through presentations and publications, poster presentations, software, and patent disclosures. The policies governing the ownership of intellectual property are available upon request.

Want to learn more about a wide variety of the machines and materials currently being used in additive manufacturing/3D printing? Check the Senvol Database created and maintained by Senvol, LLC.